Mooney viscosity—PC type factories|mooney viscosity examples : Brand Mooney viscosity measures the stiffness of the uncured compounds, otherwise known as the compound’s viscosity. The appropriate standards associated with this test are IS0 289, ASTM . WEBJapa Nordestina está em processo de regularizar a entrada no OnlyFans. A reportagem da TRIBUNA DO NORTE conversou com vários potiguares que estão nesses sites de .

{plog:ftitle_list}

Resultado da 4 de out. de 2022 · Um topo de bolo para batizado fácil de imprimir vai deixar o seu bolo maravilhoso e o momento eternizado em sua memória. .

Mooney viscosity measures the stiffness of the uncured compounds, otherwise known as the compound’s viscosity. The appropriate standards associated with this test are IS0 289, ASTM . The Mooney viscometer is an inexpensive instrument (cost and maintenance) that is easy to use and, above all, available in the great majority of factories producing natural .

Mooney viscosity measurements have been found helpful in estimating the processing characteristics of rubbers. They must be supplemented by other types of tests, however, .This part of ISO 289 specifies a method using a shearing-disc viscometer for measuring the Mooney viscosity of uncompounded or compounded rubbers. 2 Normative references. The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition .The Mooney Viscosity of Raw Natural Rubber G.M. BRISTOW* Non-standard Mooney test parameters have been derived for a range of raw natural rubber grades in an attempt to obtain information other than a simple assessment of viscosity. Increasing the pre-heat time to 5 tnin and observing the torque-time relation over 1-4 min

아주 대표적인 평가 기기 Mooney Viscometer (무니 점도계)에 대해서 포스트를 해보려고 한다. 대표적인 무니 점도계는 아래와 같이 생겼다. 몇개의 경쟁사가 있겠지만. Alpha Technologies가 개인적으로는 가장 익숙하다. 위의 그림과 같이 .Mooney viscosity measurements have been found helpful in estimating the processing characteristics of rubbers. They must be supplemented by other types of tests, however, before a comprehensive measure of processibility can be obtained. References. 1.Mooney viscometer The sample cavity of the Mooney vis-cometer is shown in Fig. 1. The rotor is embedded in a sample and the torque required to move the rotor at 2 rpm is measured. A typical Mooney viscosity measurement is the ML1+42. This test uses a 1 minute preheat with the motor off and then 4 minutes with the motor on at 2 rpm.

influence of feed compositions on rubber Mooney viscosity† Ge He, ab Tao Luo,*a Yagu Dang,a Li Zhou,a Yiyang Daia and Xu Ji*a Mooney viscosity is an essential parameter in quality control during the production of nitrile-butadiene rubber (NBR) by emulsion polymerization. A process model that could help understand the influence of The SMV-301 / 301RT allows the user to measure the Mooney viscosity, scorch time, minimum Mooney viscosity, and other characteristics of rubber in accordance with JIS, ISO, and ASTM test methods. With outstanding temperature recovery characteristics and easy operability, it can also be used for stress relaxation measurements or for tests that . On the other hand, in most rubber/tire factories, the Mooney viscosity can be only obtained offline using laboratory analysis several hours later after a batch has been discharged [1,2]. In the absence of an economical or effective online measurement, soft sensors (or inferential sensors) could serve as an alternative solution [3–7].

The results have shown that a change of 1 from the test temperature of 100 or 125 results in a 1.5-3% change in Mooney viscosity, depending on the type of rubber tested. 2.2.2. CLOSURE AND HOLDING PRESSURE During the test it is extremely important that the platens and dies be held closed with a force of 11500+500N.3 To obtain the correct .

mooney viscosity test

The Mooney viscosity of the sample set was measured by the standard method and the values were in the range 65–95 units. The samples were divided in two subsets, one for calibration, containing 70 samples, and the other for external validation, containing the remaining 30 samples. The Mooney viscosity average values and their standard .SKZ132 Mooney viscosity—PC type Used to Raw rubber or rubber compound for the determination of Viscosity, scorch and curing index Feature of host: 1. Computer control, Data display, Automatic calibration 2. Imported intelligent digital temperature controller, easy to . However, if the Mooney viscosity is too low, the physical and mechanical properties of vulcanized products are poor. From the Fig. 4, we can see that with the extension of storage time, the Mooney viscosity of NR shows an increasing trend. The Mooney viscosity of NR goes from 76 to 83 with storage time from 0 to 48 h with a rate increase of 9.21%.Generally speaking, this type of equipment, its operation and the interpretation of the results are too complicated to be used as a standard quality control tool at present. . On Mooney viscosity and Mooney stress relaxation I. J. Appl. Polym. Sci. 1999, 74 pp. 1207–1219 [5]

Abstract The direct near‐infrared spectroscopic reflectance measurements of prevulcanized natural rubber (brown crepe) was employed for determination of its Mooney viscosity. NIR reflectance spectra were obtained for a total of 100 samples whose Mooney viscosity (VM in the range 68–95 units) have been determined by the standard reference .Professional Rubber Mooney Viscometer is used for determinating rubber's viscosity and vulcanization index. Sample in a certain temperature and pressure, the rotor to a certain degree of rotation torque on the sample to a certain .

Certifi cate No. 0395 Certifi cate No. 3088 Technical Specifi cations Design Spec. ISO No. 289/ ASTM D1646 Electrical Single Phase 220/240V 50HZ, 110v 60Hz. Pneumatics Filtered air, 4.2 Kg/cm, (60 Psi) Die Confi guration Standard, large or small rotor Rotor Large or small Rotation Speed 0.21 Radians/sec. (2 rpm.) Calibration Fully automatic Temperature Control 3 .

In most rubber and tire factories, however, the Mooney viscosity can only be determined through manual analysis, which often takes 4∼6 h after a batch has been discharged, while the duration of .The average molar mass obtained by gel permeation chromatography (GPC) has been proposed for determination or has been associated with the Mooney viscosity.[2,3] However, the proposed method requires the use of a GPC instrument and is another time-consuming technique that prevents rapid, in situ determination of the Mooney viscosity.5. The maximum test time: Mooney: 10min; Scorch: 120min (modification time during testing) 6. Mooney value of measuring range: 0 to 200 7. Mooney value resolution: 0.1 Mooney value 8. Mooney value measurement accuracy: ± 0.5 Mooney value 9. Calibrate accuracy: 100±0.5 Mooney value 10. Rotor speed: 2 ± 0.02r/min 11.Mooney Viscosity, Find Details and Price about Mooney Viscosity from Mooney Viscosity - Jiangsu Mingzhu Testing Machinery Co., Ltd. . Business Type: Manufacturer/Factory. Business Range: Instruments & Meters, Manufacturing & Processing Machinery. Management System Certification: ISO 9001.

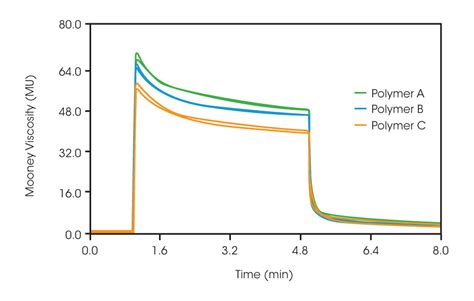

Mooney viscosity After roll molding, 5 cm round pieces of rubber were cut, and Mooney viscosity was determined according to ISO 289-1-1994 by Mooney viscometer. The temperature of testing was 100 C. The rubber sample was preheated at 100 C for 1 min, followed by a shear for 4 min to measure the Mooney viscosity. Molecular weight2. Test data: contains the Mooney viscosity, scorch various data; 3. Test curve: Mooney viscosity curve, Mooney scorch curve, temperature curve of the upper and lower mold 4. Modify the time during testing 5. The test data can be saved automatically 6. A number of test data and curves can be displayed on one piece of paper, and used the mouse .Different rubber compounds may exhibit varying Mooney Viscosity values based on factors such as the type of rubber, the presence of additives, and the degree of vulcanization. The test is particularly useful for comparing different formulations and optimizing rubber processing parameters to achieve desired properties and performance in the .Mooney Viscosity The Mooney Viscosity test is the most popular test method for characterizing polymers and uncured rubber materials. As defined by international standards, the sample material is preheated for a defined period in a closed die cavity, then 48. sheared by the embedded rotor at a constant rate. The Mooney Viscosity is recorded

Mooney viscosity is the viscosity reached after the rotor rotates for a given time interval (Mooney time setting). JIS K 6300 specifies measuring the Mooney viscosity four minutes after the preheating time ends. However, SMV-301/301RT models allow the user to specify up to ten Mooney viscosity detection times. Therefore, real-time and precise detection of the product Mooney viscosity in the continuous industrial production of NBR is paramount for the quality control of product and its processability thereafter. 2 However, in practice the online detection of Mooney viscosity is nowadays not possible, while standard characterization procedures with the .

Note 1: Viscosity as used in these test methods is not a true viscosity and should be interpreted to mean Mooney viscosity, a measure of shearing torque averaged over a range of shearing rates. Stress relaxation is also a function of the test configuration and for these test methods the results are unique to the Mooney viscometer.

mooney viscosity examples

1 dia atrás · 1. to make suitable to requirements or conditions; adjust or modify fittingly. They adapted themselves to the change quickly. He adapted the novel for movies. intransitive verb. 2. to adjust oneself to different conditions, environment, etc. .

Mooney viscosity—PC type factories|mooney viscosity examples